What is Tube Bending?

Tube bending is a metal forming process that modifies the shape of tubes and pipes to create curves and complex geometries.There are several methods and techniques for bending tubes, each with its unique benefits and applications. This blog post will provide a comprehensive look into the world of tube bending service, focusing on its various capabilities, material options, and requirements.

Whether you require round tube bending, rectangular tube bending services, or square tube bending services, our team can deliver with high accuracy and efficiency. We are your reliable tube bending specialist and strive to offer the best tube service possible.

Our diverse tube services also include custom pipe bending, CNC pipe bending, pipe bending services, and tube bending and fabrication. For those in need of additional support, we also offer pipe bending and fabrication, making us a one-stop-shop for all your tube and pipe needs.

Tube Bending Types

When it comes to manufacturing precision components, there are several different types of tube bending services available. It’s crucial to understand the different methodologies to make the right choice for your project.

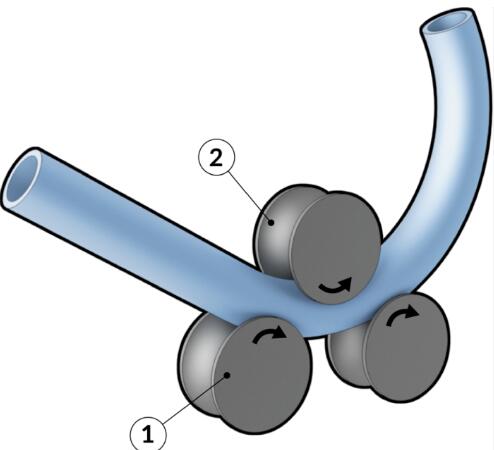

Roll Tube Bending

Roll tube bending is a process often chosen for its ability to create large radius bends. It’s especially valuable when working with custom bent aluminum components, or any project where maintaining the integrity of the material throughout the bending process is essential.

Rotary Draw Tube Bending

Rotary draw tube bending makes use of a series of dies to shape the tube, making it ideal for complex, precision-required projects, whether you’re seeking a custom tube shape or working on automotive components.

Mandrel Tube Bending

When precision and a smooth finish are paramount, the mandrel tube bending service is often the choice. This process uses a solid rod or ‘mandrel’ inside the tube to maintain its shape during bending, which makes it a great fit when dealing with bent stainless steel tubing or similar materials.

Compression Bending

Compression bending is an economical choice for simpler tube bending projects. Despite its simplicity, it’s still a very versatile technique and can be applied to a range of materials and projects.

Material Options

Tube and Pipe Materials

Various tube and pipe materials can be shaped using our custom bending services. This includes but is not limited to stainless steel, brass, and aluminum. We choose the material based on your specific needs and the performance criteria of the final product. For example, stainless steel tube rolling might be the best choice for a project requiring high durability and resistance to corrosion.

Round Tube

Round tube bending is one of the most common requests we get. Our CNC tube bending services can handle round tubes of varying sizes and materials, ensuring a perfect fit for your needs. Round tubes are often used in structures that require a balance of strength and weight.

Rectangular Tube

Rectangular tube bending is another service we excel at. Rectangular tubes can provide greater strength in one direction and are often used in buildings and bridges. We can work with a variety of materials and sizes to create the exact custom tube your project requires.

Square Tube

Square tube bending is ideal for projects that require uniform strength in all directions. Square tubes are commonly used in the construction and manufacturing of furniture, structures, and various other applications. Our square tube bending services cater to a variety of sizes and materials, ensuring the highest quality result for your specific needs.

Bend Requirements

Parameters for Building a Quote

When requesting a quote for a tube bending service, you should provide detailed information to ensure an accurate estimate. These parameters include:

- Material type: Specify whether you require stainless steel tube bending, aluminium tube bending, or another material.

- Tube profile: Indicate whether you need bending for a round tube, square tube, or rectangular tube.

- Tube diameter and wall thickness: Mention the required size and the thickness of the tube wall for accurate estimation.

- Bend radius: Provide the desired bend radius, which can be defined in terms of center line radius or bend radii.

- Quantity: Specify the number of bends needed and the total quantity of tubes.

Center Line Radius

The center line radius (CLR) is a crucial measure for the tube bend. It is the distance from the center of the bend to the center of the tube. For example, if you need to bend a tube into a semi-circle, the CLR would be the radius of this semi-circle.

Bend Radii

The bend radii are a measure of the curvature of the bend. For a specific tube diameter, you need to specify a minimum bend radius to ensure the tube’s integrity during and after the bending process. The bend radius is often specified in relation to the tube diameter.

Tube Profile

Specify the profile of the tube to be bent, whether it is a round tube, square tube, or rectangular tube. Each profile has different characteristics and applications, and some may require specific bending processes or tools.

Tube Wall Thickness

The tube wall thickness is another critical parameter. It influences the strength and flexibility of the tube and can affect the minimum bend radius. Specify the wall thickness to ensure a successful tube bending process and to avoid potential issues such as crimping or buckling.

Tube Diameter

The tube diameter is an essential factor in the tube bending process. It can directly influence the tube’s capacity to withstand pressure, the bend radius, and the bending process. Indicate the diameter to ensure the correct tooling and procedures are employed during the bending process.

Tube and Pipe End Finishing Services

Tube bending services are often complemented by end finishing services to add value to the final product and to ensure it is ready for use.

Options for Tube and Pipe Ends

Depending on your project requirements, you may choose different end finishing options. These include:

- Flaring: This process widens the end of the tube, useful in plumbing or automotive applications where tubes need to be connected.

- Swaging: This involves reducing the tube’s diameter at the end, allowing for a secure fit with other components.

- Beading: A bead is created at the end of the tube to help secure hoses or provide a finished look.

- Threading: Threads are added to the tube end, enabling it to be screwed into other parts.

- Deburring: Any sharp edges or burrs created during the tube cutting or bending process are removed to ensure safe handling and assembly.

Benefits of End Finishing

End finishing provides several benefits:

- Improved fit and assembly: By altering the tube ends, you can ensure a snug fit with other components, facilitating easier and more secure assembly.

- Enhanced safety: End finishing processes like deburring remove sharp edges, reducing the risk of injury during handling.

- Better aesthetics: A well-finished tube end can provide a more professional look, enhancing the overall aesthetic of the final product.

- Increased lifespan: Certain end finishes can add strength to the tube ends, which often experience more wear, thus increasing the product’s lifespan.

Industries Served

Tube bending services play a critical role in many industries, creating customized components for a variety of applications. From automotive to aerospace, the demand for high-quality bent tubes is vast and varied.

- Automotive:

- Aerospace:

- Construction:

- Medical

- Energy

- Marine Industry

- Appliances

- Electronics

- Music

Why Choose Chengli for Tube Bending?

Experience and Expertise

We have a team of tube bending specialists who have honed their skills over many years. We’ve developed a keen understanding of the complexities involved in custom tube bending and how to deliver high-quality results every time.

Range of Services

Our tube services go beyond basic bending. We offer CNC tube bending services, mandrel bending, roll bending, and more. We also have the capabilities for tube forming, tube fabrication, and end finishing services, providing a comprehensive solution for our clients.

Material Variety

Whether you’re looking for aluminum tube bending, bending steel tubing, or bending thin wall tubing, we’ve got you covered. We work with a wide range of materials, including aluminum, steel, brass, and stainless steel.

Customization

We excel in providing custom tube bending services tailored to your specific requirements. Our custom tube benders and cnc tube bending services ensure precise, high-quality results, whether for a one-off project or large-scale production.

Quality Assurance

With our rigorous quality control measures, we ensure that every piece we produce meets the highest standards. We are a tube bending company that values consistency and reliability.

Efficient and Cost-Effective

Our advanced machinery and skilled professionals enable us to provide efficient services that can significantly reduce production time and cost.

Conclusion

To sum it up, tube bending service is a vital process in many industries, offering endless possibilities in the creation of complex structures and components.

When it comes to selecting a service provider, Chengli Hardware stands out as a leading tube bending company. We offer comprehensive services, a broad range of material options, custom solutions, and a commitment to quality and efficiency.

Next time you require tube bending services, consider the valuable information shared in this article and remember that Chengli Hardware is here to provide you with a superior tube bending service tailored to your needs.