Sheet Metal Fabrication Services

Our sheet metal fabrication services stand out due to our expertise, state-of-the-art equipment, and commitment to quality, allowing us to produce precise and complex parts with fast turnaround times and competitive pricing.

- All uploads are secure and confidential.

Our Custom Sheet Metal Fabrication Services

Chengli offers a wide range of capabilities to meet the needs of our clients, including precision cutting, bending, welding, and assembly.

Our fast laser cutting machines allow us to offer high-quality parts with short lead times.We can work on sheets as large as 2000mm x 60000mm.

Waterjet cutting involes using a high-pressure stream of water mixed with an abrasive substance.

Plasma cutting uses a focused jet of superheated, electrically ionized gas to cut through metal.

What is Sheet Metal Fabrication?

Sheet metal fabrication is the process of transforming flat sheets of metal into finished products using various techniques such as cutting, bending, punching, and assembling. It can be used to create a wide range of products, from simple brackets and enclosures to complex machinery and components.

Chengli could fabricate many kinds of metal material, including aluminum, brass, steel,copper, and stainless steel .The thickness ranges from 0.1mm to 30mm. No matter you request prototypes,low volume or high volume, or you need us to supply the assembly service, such as welding, installing and finishing, we could fulfill your requests with high quality and competitive prices.

Advantages and Challenges of Sheet Metal Fabrication

Sheet metal fabrication is an ideal manufacturing process for metal components, capable of supporting both prototyping and production quantities.

Advantages of Sheet Metal Fabrication

- Sheet metal fabrication can be tailored to meet any design requirement, making it a versatile option for a variety of projects.

- Compared with other processes, such as stamping, casting, or injection, you do not need to apply expensive tools to test your ideas.

- Sheet metal fabrication can often be more cost-effective,as it involves less waste and requires less processing time.

Challenges of Sheet Metal Fabrication

- Sheet metal fabrication requires a high degree of precision and specialized skills. Without experienced technicians, the quality of the parts may suffer.

- Fabricating large sheet metal parts may be limited due to the need for larger materials and equipment.

- Sheet metal fabrication is a handcrafted process, so there may be some unavoidable errors and variations. Therefore, extra care must be taken when producing high-precision parts.

Main Types of Sheet Metal Fabrication

Sheet metal processing is the process of cutting, bending and stamping metal sheets to make various shapes of parts or components. The process of sheet metal processing mainly includes the following aspects.

- Sheet metal stamping involves using a stamping press and a tool and die set to form flat sheets of metal into a desired shape through high-pressure application. It is always good when you have high-volume needs.

- Sheet metal bending could change the angle of the plate, such as bending the sheet into a V-shape, a U-shape, etc. We could use molds to bend the parts, another option is to use a bending machine.

- Sheet metal forming is the process of bending the flat area of sheet metal to a certain angle, arc shape, stretching, twisting, etc.

- Tube bending and fabrication e and aerospace applications.

- CNC turret punching when you need to create holes, squares, or basically any shape or pattern in flat metal sheets,you could consider using CNC turret punching.

- Welding is a manufacturing process and technology that uses heat, high temperature, or pressure to join metal or other thermoplastic materials.

How does Sheet Metal Fabrication Work?

Sheet metal fabrication involves cutting, bending, and shaping thin sheets of metal to create a variety of products. The process typically starts with a design or blueprint, and then the metal sheets are cut into the desired shape using tools such as shears or lasers or plasma or waterjet. Then the metal is formed into the appropriate shape using techniques such as bending or rolling. Finally, the pieces are assembled and welded together to create the final product. The process requires skill and precision to ensure that the finished product meets the desired specifications.

Sheet metal fabrication could be used in many applications, including aerospace, defense, automotive, energy, industrial, medical, dental, and consumer products.

Sheet Metal Fabrication Tolerances

It’s always best to consult with a Chengli’s expert to determine the appropriate tolerances for your particular project.

| Dimension tolerance | Metric Units | Inch Units |

|---|---|---|

| Hole Sizes | +/-0.0762mm | +/-.003” |

| Hole to Hole | +/-0.127mm | +/-.005” |

| Hole to Edge | +/-.0.254mm | +/-.010” |

| Hole to Bend | +/-.0.381mm | +/-.015” |

| Bend to Bend | +/-0.508mm | +/-.020” |

| Whole Forming | +/- 0.762mm | +/- 0.030" |

| Linear dimensions | +/- 0.254mm | +/- 0.010" |

| Angularity | +/- 2 ° | +/- 2 ° |

| Bend Angle | +/- 1 ° | +/- 1 ° |

Sheet Metal Fabrication Materials

Chengli Hardware works with a variety of materials, including stainless steel, aluminum, brass,steel and copper with material thicknesses 0.1-30mm, to provide customized solutions for your unique application.

Aluminum 1060

Aluminum 3003

Aluminum 5052

Aluminum 5083

Aluminum 6061

Aluminum 6063

Stainless steel 301

Stainless steel 302

Stainless steel 304

Stainless steel 316

Stainless steel 409

Stainless steel 430

Stainless steel 420

Carbon steel:1006, 1008, 1010

Alloy steel:SAE1050, SAE1065,

Tool steel

Galvanized Steel

C23000

C26000

C101

C110

Phosphor Bronze

Acrylic( PPMA)

PC

Sheet Metal Fabrication Finish

We offer a variety of organic coating solutions to meet our customers’ special requirements. If you do not see the material finish combination you are looking for, please fill the quote sheet, and our experts will help you.

The metal stamping parts are typically deburred and cleaned, with a surface finish that is smooth but not polished or textured.It is characterized by visible tool marks, scratches.

Polishing can improve aesthetics and reduce surface roughness using a buffing or abrasive process.The surface rougness could reach to Ra0.8μm ,even Ra0.4μm.

A process where the surface of the metal is roughened or textured by blasting it with abrasive particles or media, such as sand or glass beads.This can help with grip or visual appeal.

Anodizing is a surface finishing process that produces a protective oxide layer on the surface of aluminum parts.

Type II( MIL-A-8625 Type II), provides corrosion resistance and can be done in different colors, such as clear, black, red, and gold.

On the other hand, Type III anodizing, also known as MIL-A-8625 Type III “hardcoat,” is thicker than Type II and creates a wear-resistant layer in addition to corrosion resistance.

Alodine is a chemical process, used to create a protective layer on the surface of the metal stamping parts, improving corrosion resistance and bonding capabilities.

This involves the surface of the metal stamping parts is brushed with an abrasive material, creating a textured or satin-like finish.

A layer of chromium is electroplated onto the surface of the metal stamping parts, creating a highly reflective and corrosion-resistant finish.

Passivation is a chemical process that removes surface contaminants and creates a passive layer on the surface of the metal part, protecting it from corrosion.

Electrophoresis coating, also named E-coating, is an electrocoating process where the metal is immersed in a bath of paint particles and an electric current is applied to create an even coating. Normally the color is black.

Phosphate Plated is a chemical and electrochemical reaction to form a phosphate chemical conversion film. This process is normally applied to steel materals.

Carburizing is a heat treatment process that introduces carbon into the surface layer of the metal to improve hardness and wear resistance.

A layer of zinc is electroplated onto the surface of the metal stamping parts, providing corrosion resistance and an attractive finish. We could supply white,blue,yellow,green colors.

Nickel electroplating is commonly used to improve the corrosion resistance, wear resistance, and surface finish of metal parts.

Nickel electroless plating is a chemical process that deposits a layer of nickel onto the surface of the metal part, creating a uniform and corrosion-resistant finish.

Powder coating is electrostatically applied to the metal stamping parts, which are then baked in an oven to create a durable and attractive finish. A wide variety of colors are available to create the desired aesthetic.

Liquid paint is applied to the surface of the metal stamping parts, providing an attractive finish but typically less durability than powder coating.

This involves the application of a layer of tin to the surface of the metal for improved corrosion resistance and solderability

Black oxide is a chemical process that creates a dark, corrosion-resistant finish on the surface of the metal part.

PVD is an industrial manufacturing process, i.e., vacuum coating, that gives products a beautiful metallic texture and excellent performance. It applies for metal and plastic material, a kind of expensive finishing process.Gold Plating provides good corrosion and tarnish resistance with excellent solderability

Gold Plating provides good corrosion and tarnish resistance with excellent solderability. Normally the thickness is 0.00002″ – 0.00005″.

Silk printing, also known as screen printing or serigraphy, is a printing technique that uses a woven mesh to support an ink-blocking stencil.

Sheet Metal Fabrication Design Guidelines

We follow sheet metal design guidelines to ensure the quality and manufacturability of your projects.

| Feature | Description (T = Material Thickness) | Photo |

|---|---|---|

| Material thickness | choose the same thickness for the sheet metal parts |

|

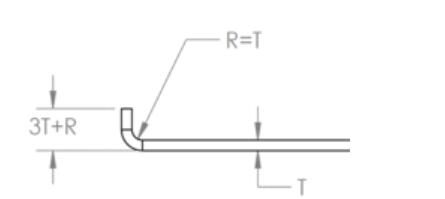

| Minimum inside bend radius | 1xT |

|

| Minimum bend length | 3xT+bend inside radius(R) |

|

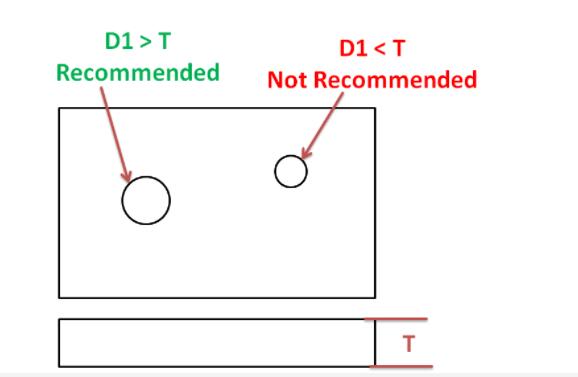

| Hole diameter | > T |

|

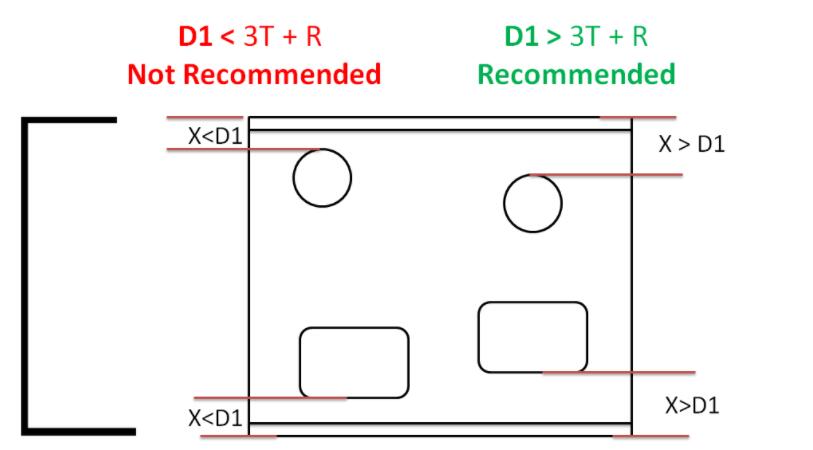

| Minimum hole/ slot distance to bend edge | >3T+R(inside bend radius) |

|

| Center hole distance | 6T |

|

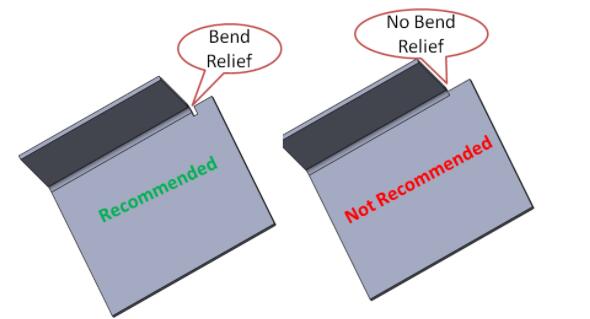

| Bend relief | >2T+inside bend radius |

|

Why Use Chengli's Sheet Metal Fabrication Services?

Thanks to our highly efficient process, we provide quick, accurate prototypes, small bath and mass production.

Competitive Prices

Our sheet metal fabrication services are cost-effective due to our advanced manufacturing processes, efficient production techniques, and experienced engineering team. We are committed to offering competitive pricing without sacrificing quality or delivery times.

Fast and Reliable Delivery

Quality parts for prototypes are delivered within our 5-day standard lead time. Quality parts for mass production are delivered in 12 days, even faster.

Manufacturing Capabilities

Our state-of-the-art facility has a wide range of cutting machines, bending machines, welding machines, and other advanced manufacturing equipment. We have the capability to produce complex parts with tight tolerances, and we offer a variety of secondary operations to complete your parts to your exact specifications.

Quality Assurance

We maintain rigorous quality control standards throughout our entire manufacturing process to ensure that every part we produce meets or exceeds customer requirements. Our quality management system is certified to ISO 9001:2015, and we utilize advanced inspection equipment and techniques to verify the accuracy and consistency of our products.

See What Our Customers Say About Us

See what our satisfied customers have said regarding how we fulfilled their requirements.

Sheet Metal Fabrication FAQ

Below you will find the answers to the most common questions we get about the sheet metal fabrication process.

What is Sheet metal fabrication?

Sheet metal fabrication involves transforming flat steel, stainless steel,and aluminum sheets into various metal structures or products through cutting, punching, folding, and assembly.

What is the difference between sheet metal fabrication and stamping?

Sheet metal fabrication involves cutting, bending, and assembling sheet metal to create a finished product. Stamping, on the other hand, involves using a stamping press to press a sheet metal blank into a specific shape or form.

What are some common sheet metal fabrication techniques?

Some common sheet metal fabrication techniques include cutting (such as laser cutting, plasma cutting, or waterjet cutting), bending and forming (such as press brake forming), punching, and welding.

What are some common materials used in sheet metal fabrication?

The most common materials used in sheet metal fabrication are steel, aluminum, and stainless steel.

Sheet metal fabrication Application

From prototyping to production, Chengli has been a leading manufacturer of sheet metal fabrication parts for a wide range of industries.

Gallery of Sheet Metal Fabrication Parts

We machine low-volume and high-volume production orders for customers in multiple industries: aerospace, automotive, defense, electronics, hardware startups, industrial automation, machinery, manufacturing, medical devices, oil & gas and robotics.