In the world of manufacturing, precision and efficiency are paramount. This is where laser tube cutting service steps into the spotlight. This advanced technology revolutionizes how we cut and manipulate tubular materials. Whether you need precision cuts for industrial applications or artistic designs, laser tube cutting services have emerged as a go-to solution.

As an industry leader, Chengli Hardware, offers a suite of tube laser cutting services. Our advanced technology and skilled engineering professionals can customize laser tube cutting operations to meet the most stringent quality standards. At Chengli Hardware, we offer comprehensive laser tube cutting services that can adapt to your individual needs.

Basic of Laser Tube Cutting

The laser tube cutting process begins with a focused laser beam, directed by a laser tube cutter, which cuts through the material. The power and precision of the laser tube allow for highly accurate and efficient tube cutting, which makes it a preferred technique for various industries.

Through the laser tube cutter machine, the laser tube‘s energy is accurately applied to the material’s surface, where it heats, melts, or vaporizes the material. In some cases, a gas jet blows away the molten material to achieve the desired cut.

This intricate procedure is all done online through the laser online system, enabling precision, speed, and versatility. We at Chengli Hardware, are proud of our state-of-the-art online tube cutting capabilities, which deliver high-quality results across various applications.

Cutting Forms

Laser tube cutting services are not only about simple cuts. The precision of the CNC tube laser and the CNC laser tube cutter allows for the creation of complex shapes, patterns, and forms. This precision, combined with CNC laser tube technology, opens up a world of possibilities for tubular cutting, allowing our clients to bring their intricate designs to life.

One of the standout advantages of tube lasers and tube laser cutting machine technology is the ability to create precise through-holes in the material, which can be challenging to achieve with traditional methods. This precision simplifies subsequent bending and welding processes, increasing overall productivity.

Types of Laser Tube Cutter Machines

Diverse applications call for various machinery in the realm of laser tube cutting services. Hence, it’s essential to understand the primary types of laser tube cutting machines, to make informed decisions based on your specific needs.

Combination tube/flat sheet laser cutters

These machines are designed with versatility in mind. They can switch seamlessly between tube laser and flat sheet cutting. For operations that demand flexibility and a broad range of cutting tasks, these machines are an optimal choice.

Although these cutters might not offer the level of specialized functionality as stand-alone tube laser cutters, their ability to handle different tasks makes them a valuable asset in any production environment.

Self-contained laser tube cutters

Specifically engineered for laser tube cutting, dedicated laser tube cutter machines deliver unparalleled accuracy and efficiency. These systems cater exclusively to tubular materials, providing higher levels of precision and consistency, vital in high-volume or precision-critical manufacturing. This specificity makes these machines the go-to choice for operations that prioritize quality and uniformity above all else.

Laser Types – Fiber and CO2

Notably, the types of lasers used in tube laser cutting services can also differ. Predominantly, the industry uses fiber lasers and CO2 lasers. Fiber lasers are renowned for their efficiency and precision, frequently employed in 3D tube laser cutting.

In contrast, CO2 lasers, known for their high-power capability, are often used in pipe laser cutting service. Each laser type offers unique benefits and is suitable for different materials and applications.

Exploring Tube Shapes / Profiles and Thickness in Laser Cutting

When discussing laser tube cutting services, it’s vital to understand the distinction between the different types of tubular materials, specifically the differences between pipes and tubes, and how their shapes, profiles, and thicknesses impact the cutting process.

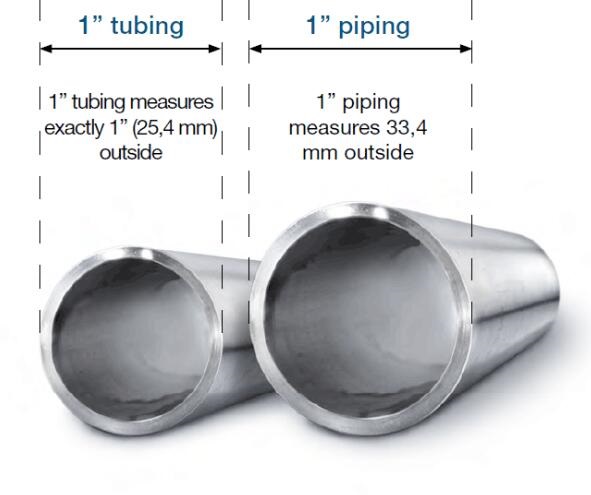

The Distinction between Pipe and Tubing

Although the terms ‘pipe’ and ‘tubing’ are often used interchangeably, they are, in fact, distinct. Pipes, typically used for conveying fluids or gases, are categorized by their inner diameter (ID) to ensure a precise flow rate.

On the other hand, tubes are often used in structural applications, categorized by their outer diameter (OD) for consistency in their structural properties. Hence, while a pipe laser cutting service might focus on creating precision cuts to facilitate fluid flow, tube laser cutting often focuses on maintaining structural integrity.

Cutting Various Tube Shapes

Laser tube cutting services excel at handling a variety of tubular profiles. Be it a rectangular, round, square, or custom profile, advanced laser tube cutters can navigate these different shapes with ease.

With the use of CNC (Computer Numerical Control) technology, such as the CNC tube laser or CNC laser tube cutter, the machine can follow complex patterns and designs, maintaining high precision throughout. Therefore, irrespective of the tube profile, you can rest assured that laser tube cutting will deliver high-quality, accurate results.

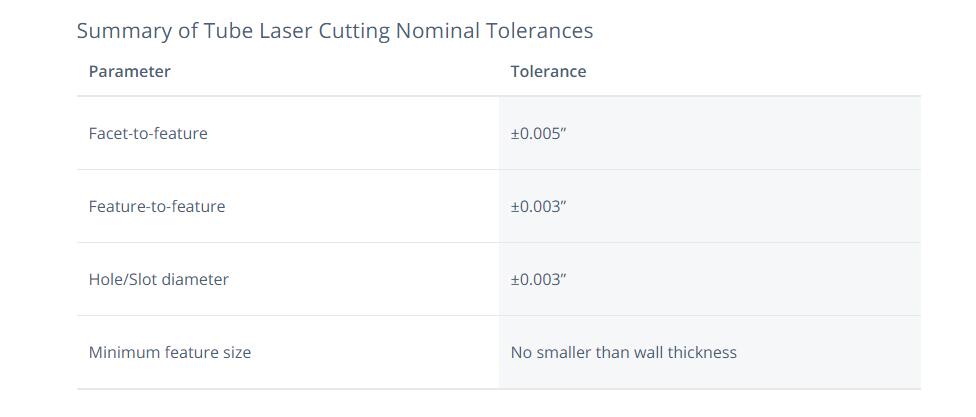

Laser Tube Cutting Tolerances

One of the critical elements that distinguish laser tube cutting services from other tube cutting techniques is the level of precision they can achieve.

The precision of laser tube cutting services shines in various aspects of the cutting process. Whether it’s feature-to-feature cuts, the diameter of holes, slots, or other detailed design elements, the laser tube cutter machine ensures consistency and precision in each aspect.

For instance, in facet-to-feature cuts, the precision comes into play in maintaining the exact distance between different features, ensuring that each feature is perfectly aligned and uniform. Similarly, when creating holes or slots in a metal tube, the precision of the laser tube cutting guarantees that the diameters of these features will be consistent, ensuring a snug fit for assembly or further manufacturing processes.

These precision levels translate to high-quality results, whether you’re working with steel tube laser cutting, aluminium tube laser cutting, or any other material in our laser tube cutting service repertoire.

Laser Cutting Tube Material Types

| Material Type | Grades for Tubes and Pipes |

| Aluminum | 1100, 2024, 3003, 5052, 6061, 6063, 7075 |

| Steel | A36, A572, A516, A514 |

| Mild Steel | 1010, 1018 |

| Alloy Steel | 4140, 4340 |

| Stainless Steel | 304, 316, 410, 420 |

| Copper | C10100, C10200, C11000 |

| Brass | C22000, C26000, C36000 |

| Titanium | Grade 1, Grade 2, Grade 5 |

Laser tube cutting has a broad scope when it comes to the types of materials it can handle. Let’s explore the wide variety of materials that are suitable for this process.

- Steel: Both laser cutting steel tubing and laser cutting steel tube are commonplace. This includes mild steel and stainless steel, which are both prevalent in the manufacturing sector.

- Aluminum: The process of aluminium tube laser cutting is efficient and results in a clean, burr-free cut. This makes it an excellent choice for industries like aerospace and automotive, where lightweight and durable materials are essential.

- Brass & Bronze: These are also suitable candidates for laser tube cutting services. They are often used in decorative applications due to their bright gold-like appearance and corrosion resistance.

- Copper: This is a challenging material due to its high reflectivity and thermal conductivity. However, it’s possible to laser cut copper using a laser tube cutter with specific settings and precautions.

- Plastics: Certain plastic materials can also undergo laser tube cutting. The resulting edges are flame-polished, and the process can create intricate shapes and details.

Pros and Cons of Laser Tube Cutting

While laser tube cutting services offer many advantages, they come with their own set of challenges. Below, we delve into the strengths and limitations of this process.

Pros of Laser Tube Cutting

- Automation: Modern laser tube cutting machines can be semi-automated or fully automated. This automation reduces human error and increases productivity, making the laser tube cutting service more efficient.

- Minimal Material Wastage: The precision of a laser tube cutter ensures minimal wastage of materials, resulting in cost savings and a more sustainable manufacturing process.

- Intricate Cuts: Tube laser cutting services allow for the creation of intricate cuts and patterns. From square and rectangular to more complex shapes, the laser tube cutting process enables the production of diverse designs.

- Adaptability: A single laser tube cutting machine can handle a variety of materials and thicknesses, reducing the need for multiple machines and making the process highly adaptable.

Cons of Laser Tube Cutting

- Combustible Materials: The heat generated by the laser tube cutter can pose a risk when working with certain combustible materials, necessitating careful operation and management.

- High Energy Usage: Laser cutters are energy-intensive, which can contribute to high operational costs.

- Skilled Operators Required: Although laser tube cutting services can be automated, they still require skilled operators for setup, oversight, and maintenance.

- Thickness Limitations: While laser tube cutting can handle a range of materials, it is generally better suited for thinner materials. Thicker materials may require other methods like waterjet or plasma cutting.

Conclusion

The science behind laser tube cutting services is indeed profound. With its capability to deliver precise, clean cuts on a variety of materials, it is revolutionizing industries and manufacturing processes worldwide. From aluminium tube laser cutting to steel tube laser cutting, the applications are vast and versatile, capable of meeting the needs of diverse industries, be it automotive, construction, or aerospace.

If you’re looking for a laser tube cutting service that offers quality, efficiency, and precision, then your search ends here at Chengli Hardware. Our highly trained team and state-of-the-art equipment are ready to meet all your laser tube cutting needs, providing a seamless and cost-effective solution to your manufacturing challenges.